Projects You May Find Interesting

Koncept has the unique opportunity to partner on many projects. Below, you can read more about some projects you may find interesting.

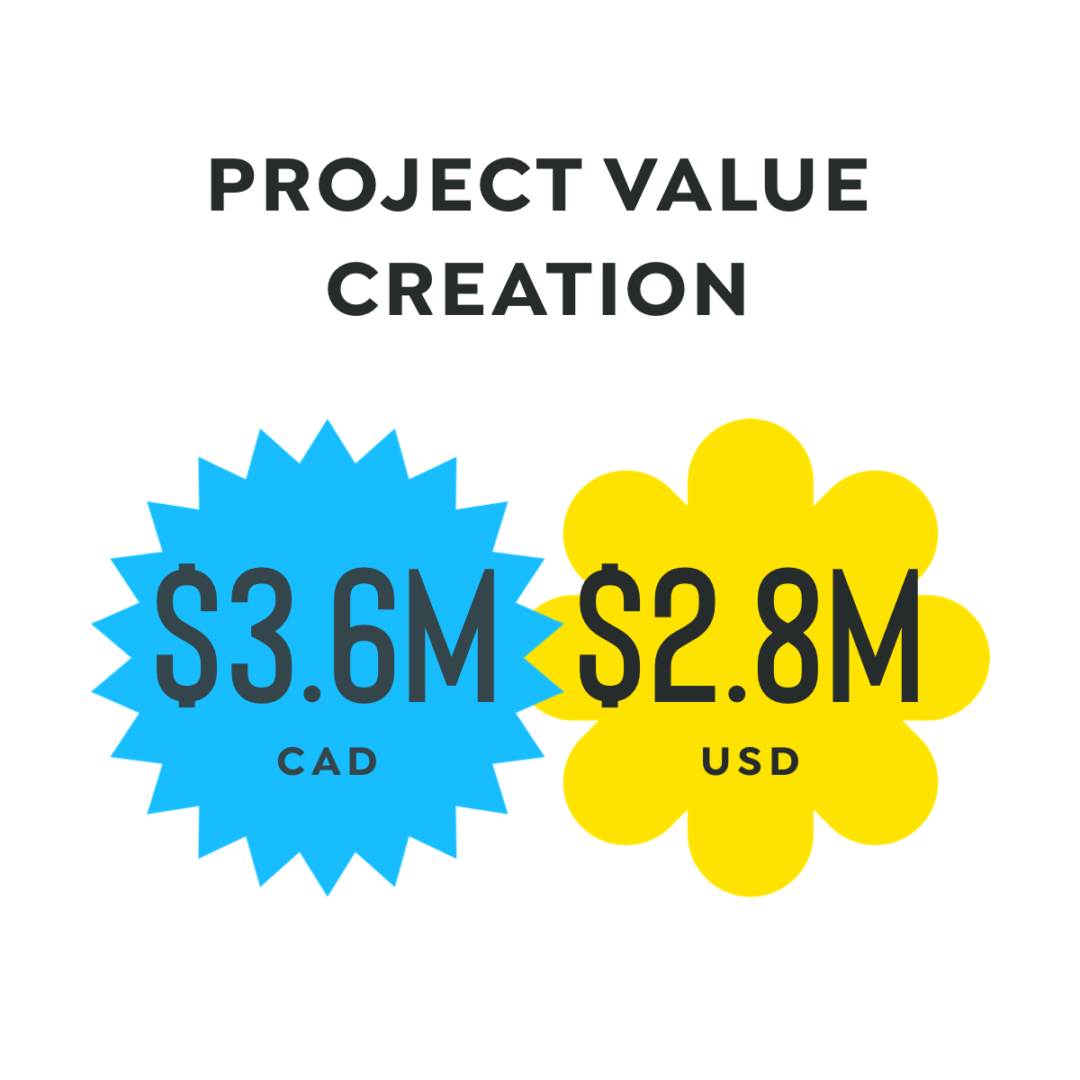

Value Creation

Project management strategies and techniques have been proven to deliver significant added value throughout the project lifecycle. Additionally, clients have recognized this by acknowledging the improved performance, reduced costs and increased efficiency that these techniques can bring. Therefore, by utilizing the right project management approach, it is possible to realize benefits such as improved customer satisfaction, better quality outcomes and even reduced time to market.

Project Testimonials

“It has been a pleasure working with you, and I appreciate all your leadership across our team. You have a unique support model, being 3rd party, but you acted as one of us, and we were very appreciative of you and your expertise.” Aaron A. AMS PJM Director ExxonMobil Account CBRE | Global Workplace Solutions. Projects you may find interesting

Project Feature

CIC Debugging Program - Fire Damper Upgrade

The Client

Environmental and Property Solutions, Imperial Oil

Contracted directly by CBRE Global Workplace Solutions on the ExxonMobil Account

Key Partners: CBRE, Koncept Projects, Williams Engineering, Bird

Project Challenge

Fire dampers form a part of the building's critical life safety system. Most importantly, they are instrumental in stopping the spread of smoke and VOCs, affording precious time for occupants to exit the building in the event of a fire safely. Regular inspection and maintenance of spring-loaded dampers were hindered due to risks like falling from heights, existing infrastructure blockages, and working in restricted areas. Therefore, if left unchecked, this could pose a regulatory risk for the client.

The Plan

To begin, we established and implemented a program delivery model for the Calgary Imperial Campus. In effect to ensure facilities upgrades were planned and executed efficiently. Thereafter, the entire program was divided into five distinct projects.

Secondly, the program delivery strategy was developed. With this intention, a cross-functional team focused on providing best overall cost and schedule value for the client.

Thirdly, the program prioritized critical needs by collecting and analyzing data with collaborating and input from the facilities team.

Fourthly, successful development and execution of the program was conducted using the following methodologies: Project Management System, Financial Controls Integrity Management System, Operational Integrity Management System, and Loss Prevention Management Safety System.

Finally, Koncept built a functional and dedicated team consisting of engineers and contractors and suppliers. Equally experienced working in an occupied campus of this size and scale, focused on providing a reliable, certified, and automated fire damper system.

The Result

E&PS and the CBRE facilities teams obtained a fully automated fire damper system compliant with all necessary regulations. Notably, this system is simple to inspect saving time and operating costs. Most importantly, work that required multiple personnel with strict safety protocols can be accomplished by a single person simply by turning a key. Ultimately, this created a simple and efficient process.

Budget $2.9M

Value Creation $1.0M

Construction Duration 13 months

Safety – No Losses

Program Score 5 – Exceeds Target

Endorsement

Stephen S. - Project Engineer Imperial Oil

I'm very happy with the team for pulling together and working with the client. Having a "One Team" mindset to work through any questions/healthy debate. Met our spend target and schedule expectations. A lot of time, patience, and dedication from the team to get there. Much appreciated!

Project Feature

CIC Debugging Program - Elevator Platform

The Client

Environmental and Property Solutions, Imperial Oil

Contracted directly by CBRE Global Workplace Solutions on the ExxonMobil Account

Key Partners: CBRE, Koncept Projects, Williams Engineering, Scott Builders

Project Challenge

During the construction of Calgary Imperial Campus, the elevator supplier contract was changed. Additionally, the elevators cores for two of the five buildings already had been designed and constructed. Ultimately, this change created an unexpected consequence between the size of elevator shafts and elevators, resulting in a mismatch. This created a challenge for the facilities maintenance team in terms of efficiently maintaining the elevator motors. The motors and components inside the elevator shaft were situated at height, resulting in a hazardous working-from-height situation.

The Plan

To ensure the safety of elevator technicians while carrying out their maintenance duties, eight steel platforms were added to the passenger and freight elevator shafts of the West Coast and North Buildings. The addition makes it easy to access the elevator equipment and motors.

Secondly, to maintain minimal noise levels below 80dBA increased constructability requirements were implemented. Ultimately, the proximity of the mining and Kearl plant operations centers necessitated such sensitivity.

Thirdly, successful development and execution of the program was conducted using the following methodologies: Project Management System, Financial Controls Integrity Management System, Operational Integrity Management System, and Loss Prevention Management Safety System.

Next, multiple stakeholder’s approvals were required due to the complexity of elevator control and operations. Furthermore, to gain regulatory agency certification several design iterations were needed.

Finally, a comprehensive quality management plan incorporating two distinct engineering teams and design initiatives was developed. Followed closely by detailed quality assurance and regulatory inspections.

The Result

The project was able to engineer and construct accessible platforms in the elevator shaft to allow safe access for continued maintenance which were a regulatory requirement of AEDERSA. Additionally, the project made use of advanced construction techniques to ensure the safety of those in the vicinity while still meeting the noise control threshold. Moreover, the project was completed without any compromises on any engineering, safety, or quality, making it a successful endeavour.

Budget $504K

Value Creation $278K

Construction Duration 3 months

Safety – No Losses

Program Score 5 – Exceeds Target

Endorsement

Kearl Mining and Remote Operations - Imperial Oil

The only feedback I have to provide is the fact that I never received any negative feedback, or concerns were brought forward from the mine team during the time of the construction. Your attention to the wellbeing of the operators in the area during the construction was much appreciated