Understanding the Hierarchy of Controls

A step-by-step approach to reducing or eliminating hazards at the workplace

By understanding the hierarchy of controls, you can ensure that you are using the most effective and cost-efficient means to protect your workers and project infrastructure. In this blog, we will explore what the hierarchy of controls is, how it works, and how it applies to different types of risks.

The Canadian Center for Occupational Health and Safety (CCOHS) defines the hierarchy of controls as a step-by-step approach to eliminating or reducing workplace hazards.

The hierarchy of controls is an important tool for understanding and managing risk in any workplace. Additionally, it provides a systematic approach to determining the best way to mitigate a given hazard, considering both the effectiveness and cost of each control.

Learn how to effectively use each hierarchy of control, its corresponding levels, and ensure the workplace is safe and compliant.

Why are Hierarchy of Controls Needed?

The hierarchy of controls are an important tool in managing safety risks. Therefore, risk management is an essential part of any project, and the hierarchy of controls is a powerful tool for assessing the effectiveness of controls. As a result, it provides a framework for understanding how different controls can be used to reduce risk and ensure safety.

How to use the Hierarchy of Controls?

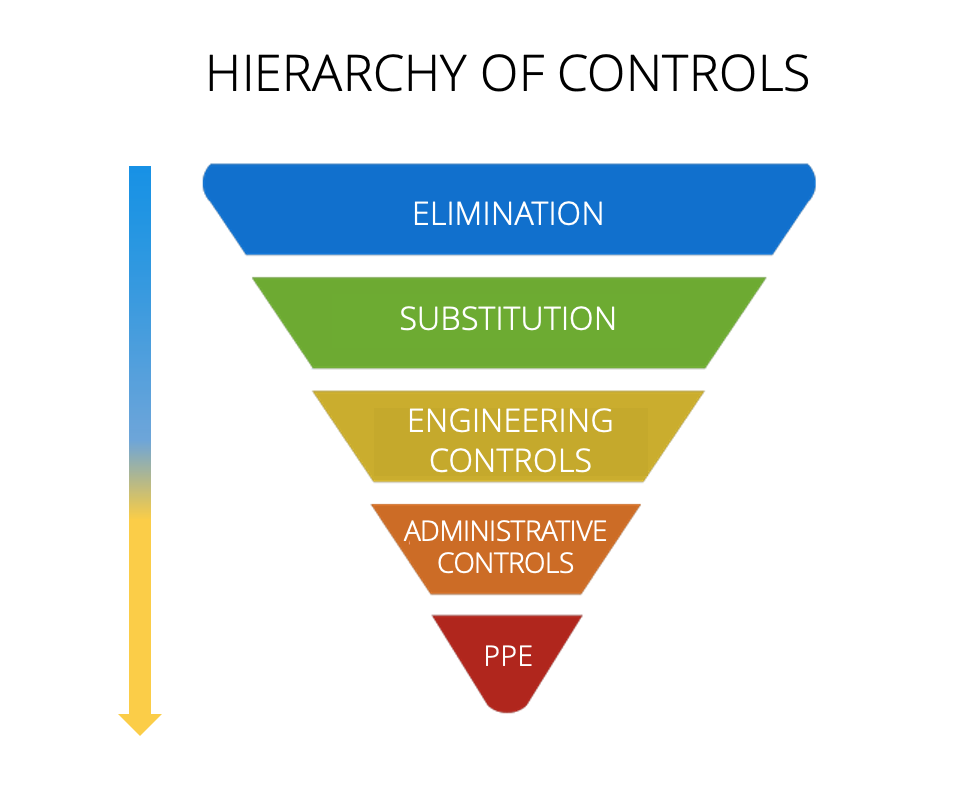

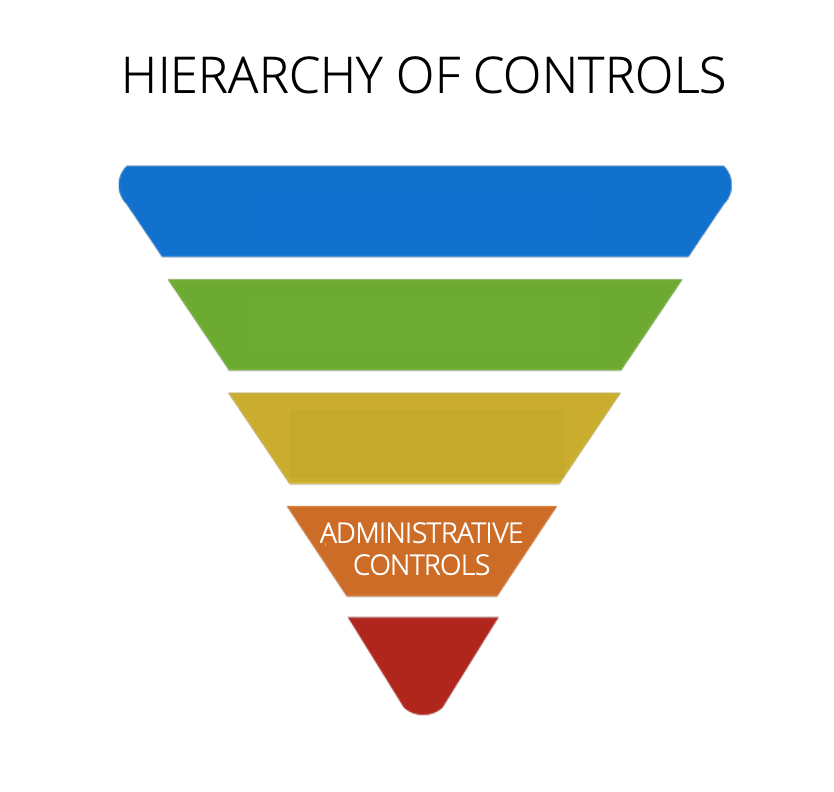

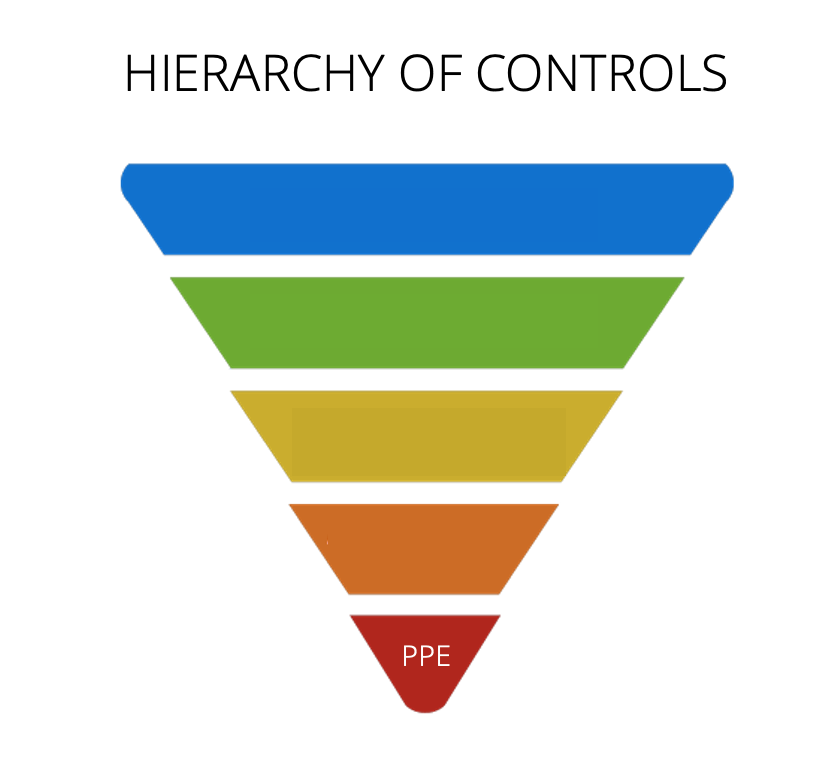

The hierarchy of controls evaluates the efficacy of different protective methods and is arranged from most efficient to least efficient. It enables people to choose the best possible option for safeguarding against potential risks.

Before picking a control technique, begin at the highest point of the flipped pyramid. Start by assessing the first layer of controls (elimination). Then move on to the second layer (substitution).

Continue assessing each layer until the bottom of the pyramid is reached. After that, determine if there are sufficient controls implemented to guarantee a safe work environment for the employees.

The Hierarchy of Controls Structure

1. Eliminate the Hazard

The greatest level of protection and the most effective control

The best way to avoid risk is to remove the hazard itself. Above all, eliminating the hazard is the most successful approach when it comes to mitigating harm.

2. Substitution

Mitigate risks by replacing them with safer options

Involves replacing a potentially hazardous material with something safer.

3. Engineering Controls

Reduce the risks through engineering changes allows hazards to be reduced at their source

Engineering controls are an essential element of workplace safety, providing a way to protect employees from hazardous materials and environments.

4. Administrative Controls

Taking precautionary measures through administrative actions can help to reduce potential harm from hazardous materials and exposure

Integrating administrative controls with other safety aspects can create a strong defence against potential threats. It’s essential to mix and match different strategies whenever possible.

5. Personal Protective Equipment (PPE)

The last line of defence and the least dependable safeguard

Wear proper personal protective equipment to safeguard yourself and others from potential injuries and harm.

How do you Apply the Hierarchy of Controls?

Apply Elimination Controls

(Physically Remove the Hazard)

Removing hazards from the workplace is an essential part of eliminating potential dangers and ensuring safety. Undoubtedly, this process can make all the difference in providing a safe work environment to employees.

Subsequently, this is the most effective way to control a risk, as the hazard is no longer present. Therefore, elimination is the most successful means of control and should be used whenever feasible.

Apply Elimination Controls Example

To illustrate, eliminating the need for a ladder using an extendable pole allows the work to be competed from the ground. Therefore, the use of a pole eliminates the fall from heights hazard.

How do you Apply Substitution Controls?

(Replace the Hazard with a Safe Option)

When removing a hazard is not an option, substitution should be the next plan of action. In this case, it’s the safest way to tackle potential risk and maintain safety in the workplace.

Substitution is a powerful tool to reduce risks, it involves replacing a potentially hazardous material with something safer. Overall, this helps make workplaces more secure and protect workers from potential hazards.

It is crucial to ensure that the risks posed by introducing a new hazard are negligible. In this situation, be cautious of replacing one hazard with another that may be equally or more hazardous.

Apply Substitution Controls Example

To illustrate, replace hazardous paint with a paint that contains low volatile organic compounds (VOCs) as a safer option.

How do you Apply Engineering Controls?

(Keep Individuals Away from the Hazard to Protect Them)

Engineering controls are a great way to avoid exposure to hazardous materials in the workplace. Most importantly, these measures allow you to remove hazards at their source.

An effective way to reduce occupational hazards is through engineering controls. Accordingly, this involves incorporating safety measures into the design of a facility, equipment, or process. By doing so, it allows projects to operate more safely and securely.

Apply Engineering Controls Example

Isolation is an effective way to reduce worker exposure to hazards by either putting distance between them or using physical barriers. Certainly, this protects employees from any potential risks associated with working in a hazardous environment.

How do you Apply Administrative Controls?

(Modify the way people work around hazards)

Administrative controls help protect people and projects from potential harm. Basically, these measures include establishing processes and procedures to make sure everyone is following the right protocol.

One way to protect workers from harm is by using administrative controls, such as setting shorter working hours in hazardous areas or having specific safety regulations in place. So that, employees limit their exposure to harmful contaminants.

Though safety precautions are important, they do have certain drawbacks as the actual hazard isn’t eliminated or reduced because of them. Therefore, integrating administrative controls with other safety aspects can create a strong defence against potential threats. It’s essential to mix and match different strategies whenever possible.

Apply Administrative Controls Example

To illustrate, establishing robust housekeeping procedures is essential for maintaining a safe and orderly work environment. Periodic assessments of these practices can ensure they are kept up to date.

How do you Apply Personal Protective Equipment (PPE) Controls?

(Protect the worker with personal protective equipment)

PPE refers to anything workers use or wear to reduce risks to their health and safety. Basically, this is the last line of defence in the hierarchy, the lowest level of protection, and the least reliable control.

Personal Protective Equipment (PPE) can help reduce the risk of harm caused by hazardous situations, but only if it is used & worn properly.

Apply Personal Protective Controls Example

To illustrate, wearing protective clothing such as gloves, coveralls, aprons, and full body suits is essential for protection from bruises, cuts, or scrapes.

Develop a Better Understanding of the Hierarchy of Controls Before Making Decisions

Gaining a better understanding of the hierarchy of controls provides greater insight when selecting the most effective mitigation strategy. Accordingly, you should consider a range of control measures and select the ones that can most effectively eliminate any hazard.

Consequently, if this is not feasible then reduce the risk as much as possible. What’s more, lowering the risk may involve one or several safety measures, working together to generate the highest level of reliable protection that is reasonably achievable.

In the same fashion, it’s important to consult your project safety representative when determining the appropriate risk control measures.